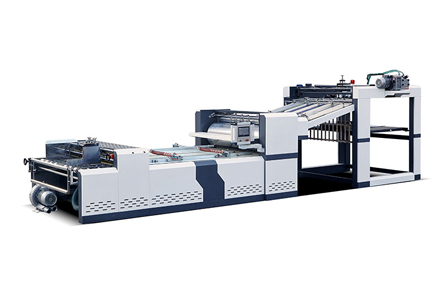

Regarding the use of the Flute Laminating Machine, since the specific model and operation interface may vary, the following general operation steps are provided for reference:

Make sure the machine is in a stable working environment and connect the necessary power and air sources (if the machine requires it). Check whether all parts of the machine are intact, especially the transmission part and the heating part. Prepare the cardboard and other related materials to be laminated as needed.

Turn on the laminating machine. There is usually an on/off switch on the back of the machine. (Plug the machine into the socket first.) If the on/off switch is in the on position but it does not seem to work, check if there is a "Standby" button to bring the machine out of sleep.

Wait a few minutes, depending on the model of the machine. Most laminating machines take at least 10 minutes to fully warm up. You can tell whether the machine is ready by looking at the machine's indicator light. Most machines have a "ready" indicator light that flashes until the machine is ready; at this time, the indicator light remains on.

Choose the speed at which you want the machine to laminate. Most machines have 10 settings; 1 being the slowest and 10 being the fastest. Laminate very thick items, such as poster board, at a slower speed. Laminate thin items, such as notebook paper, at a faster speed.

Place the items to be laminated on the machine. Slide the items up until they just touch the edge of the plastic film. Make sure the items are not overlapping or too wide for the machine. Remember that you cannot un-laminate without damaging the laminated items, press the Run button. The items should begin to pass through the laminator. You can add additional items at any time by pressing the Stop button. Once all items are in the machine, wait until the last item completely comes out the back of the machine. Press the Stop button one last time.

Slide the cutting device (located at the back of the machine) over the plastic film. This will peel the laminated material off the roll of plastic film and prepare the machine for the next user.

Clean and maintain the machine regularly, such as removing dust and checking the wear of transmission parts.

If the machine has abnormal sound or vibration or other faults, it should be stopped in time and contact professional maintenance personnel for repair.

Please note that the above steps are only general descriptions. For specific use, you need to refer to the machine's operating manual or consult the manufacturer's technical support personnel. In addition, different models of Flute Laminating Machine may have differences in operation, so you should read the relevant documents carefully and familiarize yourself with the machine's operating interface and functions before use.

GET A QUOTE